0

- 当前位置:

产品内容

适用切削范围:

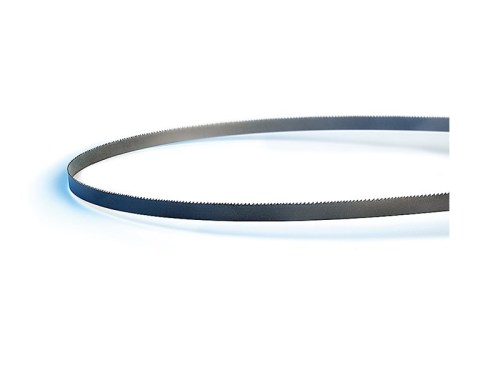

碳钢、结构钢、铸铁、低合金钢、铝铜有色金属、木材。

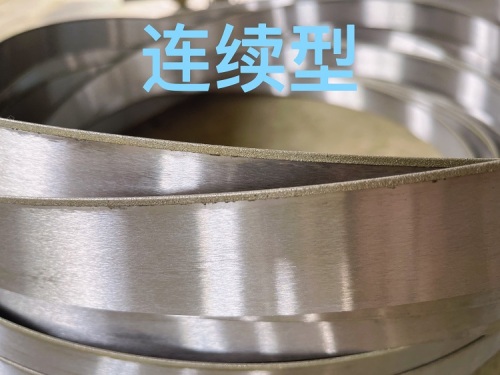

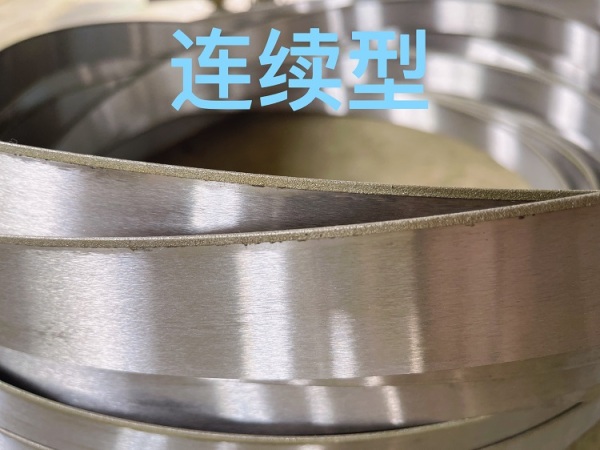

选择X32作为背材,齿材为M42超硬高速钢,品质可靠,适合基础锯切。

|

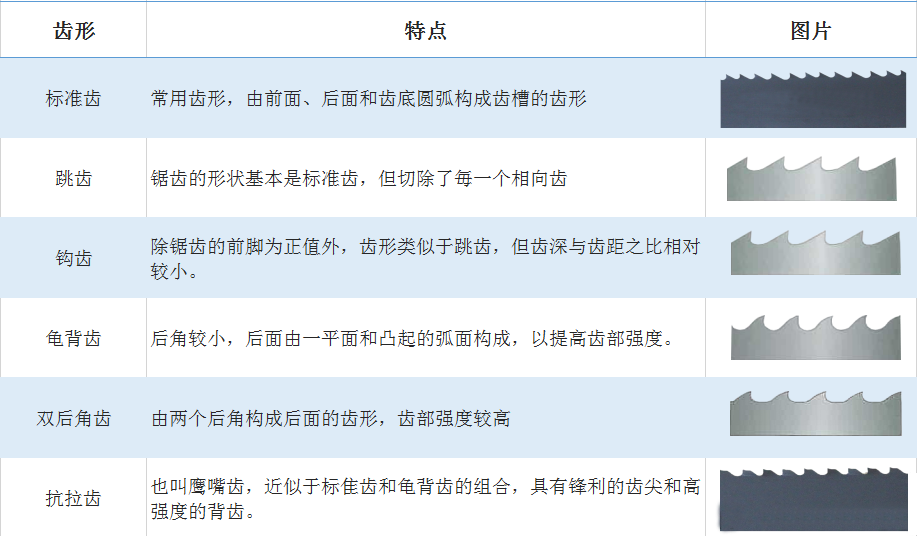

▼ TEETH PITCH INTERVAL: BI-METAL BAND SAW SLADE 双金属带锯条的主要规格 | ||

| 规格(mm) Demension | 齿形 Teeth Type | 齿距(齿数/寸) Tooth Pitch |

| 13x0.65 | 正常齿 Standard Tooth | 6、8、10、12 5/8 6/10 8/12 10/14 14/18 |

| 16x0.9 | 正常齿 Standard Tooth | 4、8、10 4/6 5/8 6/10 8/12 10/14 |

| 19x0.9 | 正常齿 Standard Tooth | 4、6、8、10 4/6 5/8 6/10 8/12 10/14 |

| 27x0.9 | 正常齿 Standard Tooth | 2/3 3/4 4/6 |

| 双后角齿 Hooked Rip Tooth | 2/3 3/4 4/6 | |

| 抗拉齿 Eagle Hook Tooth | 3/4 4/6 | |

| 34x1.1 | 正常齿 Standard Tooth | 2/3 3/4 4/6 |

| 双后角齿 Hooked Rip Tooth | 2/3 3/4 4/6 | |

| 抗拉齿 Eagle Hook Tooth | 3/4 4/6 | |

| 41x1.3 | 正常齿 Standard Tooth | 2/3 3/4 4/6 |

| 龟背齿 Rounder Back Tooth | 2/3 3/4 4/6 | |

| 双后角齿 Hooked Rip Tooth | 1.4/1.8 2/3 3/4 | |

| 抗拉齿 Eagle Hook Tooth | 3/4 4/6 | |

| 54x1.6 | 正常齿 Standard Tooth | 2/3 |

| 双后角齿 Hooked Rip Tooth | 0.85/1.3 1.4/1.8 2/3 | |

| 跳齿 Skip Tooth | 1.0/1.5 | |

| 67x1.6 | 戏后角齿 Hooked Rip Tooth | 0.75/1.0 0.85/1.3 1.4/1.8 |

| 跳齿 Skip Tooth | 1.0/1.5 | |

| 80x1.6 | 双后角齿 Hooked Rip Tooth | 0.75/1.0 0.85/1.3 |

| 跳齿 Skip Tooth | 1.0/1.5 | |

| SELECTION OF TEETH PITCH INTERVAL 双金属带锯条实心材料齿距的选择 | ||||||||||||||||||||||

| 锯切长度范围Work Length Range(mm) | 齿距TPI/1inch(25.4mm) | |||||||||||||||||||||

| 等齿距Constant Pitch | 变齿距(VL) Pitch | |||||||||||||||||||||

| 14 | 12 | 10 | 8 | 6 | 4 | 3 | 2 | 1.25 | 1 | 0.75 | 12/16 | 10/14 | 8/12 | 6/10 | 5/8 | 4/6 | 3/4 | 2/3 | 1.4/2.0 | 1.0/1.5 | 0.75/1.0 | |

| ~10 | ▲ | ▲ | ▲ | ▲ | ▲ | ▲ | ||||||||||||||||

| 10~30 | ▲ | ▲ | ▲ | ▲ | ▲ | ▲ | ▲ | |||||||||||||||

| 30~50 | ▲ | ▲ | ▲ | ▲ | ▲ | |||||||||||||||||

| 50~80 | ▲ | ▲ | ▲ | ▲ | ▲ | |||||||||||||||||

| 80~120 | ▲ | ▲ | ▲ | ▲ | ▲ | |||||||||||||||||

| 120~200 | ▲ | ▲ | ▲ | ▲ | ▲ | |||||||||||||||||

| 200~400 | ▲ | ▲ | ▲ | ▲ | ▲ | ▲ | ||||||||||||||||

| 400~ | ▲ | ▲ | ▲ | ▲ | ▲ | ▲ | ||||||||||||||||

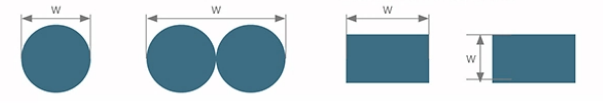

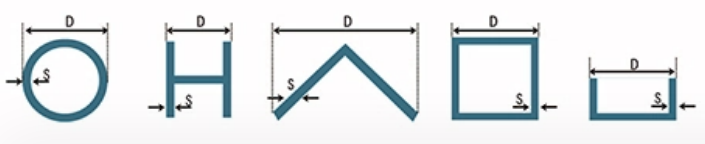

特别提醒:锯条与工件的接触长度W/mm

| ||||||||||||||||||||||

| 双金属带锯条管材或空心料齿距的选择 | ||||||||||||||

| 壁厚S/ mm | 管件外径D/mm | |||||||||||||

| 15 | 20 | 40 | 60 | 80 | 100 | 120 | 150 | 200 | 300 | 400 | 500 | 600 | >700 | |

| 2 | 14/18 | 14/18 | 14/18 | 10/14 | 10/14 | 10/14 | 10/14 | 10/14 | 8/12 | 8/12 | 8/12 | 6/10 | 6/10 | 5/8 |

| 3 | 14/18 | 14/18 | 10/14 | 10/14 | 10/14 | 8/12 | 8/12 | 8/12 | 8/12 | 6/10 | 6/10 | 6/10 | 5/8 | 5/8 |

| 4 | 14/18 | 10/14 | 10/14 | 10/14 | 8/12 | 8/12 | 6/10 | 6/10 | 6/10 | 5/8 | 5/8 | 4/6 | 4/6 | 4/6 |

| 5 | 10/14 | 10/14 | 8/12 | 8/12 | 8/12 | 6/10 | 6/10 | 5/8 | 5/8 | 5/8 | 4/6 | 4/6 | 4/6 | 4/6 |

| 6 | 10/14 | 10/14 | 8/12 | 8/12 | 6/10 | 5/8 | 5/8 | 5/8 | 4/6 | 4/6 | 4/6 | 4/6 | 4/6 | 3/4 |

| 8 | 10/14 | 8/12 | 6/10 | 6/10 | 5/8 | 5/8 | 4/6 | 4/6 | 4/6 | 4/6 | 4/6 | 4/6 | 3/4 | |

| 10 | 6/10 | 6/10 | 5/8 | 5/8 | 5/8 | 4/6 | 4/6 | 4/6 | 4/6 | 3/4 | 3/4 | 3/4 | ||

| 12 | 6/10 | 5/8 | 5/8 | 4/6 | 4/6 | 4/6 | 4/6 | 4/6 | 3/4 | 3/4 | 3/4 | 3/4 | ||

| 15 | 6/10 | 4/6 | 4/6 | 4/6 | 4/6 | 4/6 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 2/3 | ||

| 20 | 4/6 | 4/6 | 3/4 | 3/4 | 3/4 | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | |||

| 30 | 3/4 | 3/4 | 3/4 | 3/4 | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | ||||

| 50 | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | 1.4/2.0 | ||||||

| 75 | 2/3 | 2/3 | 2/3 | 1.4/2.0 | 1.4/2.0 | 1.4/2.0 | ||||||||

| 100 | 1.4/2.0 | 1.4/2.0 | 1.0/1.5 | 1.0/1.5 | ||||||||||

| 150 | 1.4/2.0 | 1.4/2.0 | 1.0/1.5 | 1.0/1.5 | ||||||||||

| 200 | 1.0/1.5 | 0.75/1.0 | 0.75/1.0 | |||||||||||

| 250 | 0.75/1.0 | 0.75/1.0 | ||||||||||||

| >300 | 0.75/1.0 | |||||||||||||

提醒说明:若为多个工件成捆,成束锯切、需将工件壁厚乘以二后作为壁厚S的厚度,然后对照该表查对  | ||||||||||||||

| ▼SELECTIN OF CUTTING PARAMETERS 双金属带锯条切削参数选择表 | ||||||||

| 被切割材料 Work Material Class | 切削速度 Cutting Speed (m/min) | 切削效率cutting Rate(cm²/min) | ||||||

| ~Ø25 | Ø25~Ø50 | Ø50~Ø75 | Ø75~Ø110 | Ø110~Ø150 | Ø150~Ø200 | Ø200~ | ||

| 易切削钢 Free-cutting Steel 结构钢 Structural Steel | 80~90 | 25~35 | 40~50 | 50~60 | 55~70 | 70~90 | 75~85 | 85~95 |

| 表面硬化钢 Case-hardened Steel 调制钢筋 Hardened and Tempered Steel | 45~75 | 20~25 | 25~35 | 30~40 | 35~50 | 40~60 | 40~50 | 35~45 |

| 碳素工具钢 Tool Steel Unalloyed 轴承钢 bearing Steel | 40~60 | 30~35 | 30~40 | 40~50 | 30~35 | |||

| 合金工具钢 Tool Steel Alloyed 高速钢 High Speed Steel | 30~40 | 15~20 | 20~25 | 25~30 | 30~35 | |||

| 不锈钢 Stainless Steel | 20~35 | 10~15 | 15~20 | |||||

| 耐热钢 Heat-resistant Steel 高温合金钢 High-temp alloyed | 15~25 | 5~10 | 7~13 | 15~15 | ||||

产品推荐 Products